-

Search

Properties

Creep and Stress Relaxation

As a critical design component in material applications that need long-term dimensional stability, Vectran™ LCP fiber performance is superior to competitive materials. These characteristics are important in applications like sailcloth, halyards, bowstring, marine cables and robotic tendons.

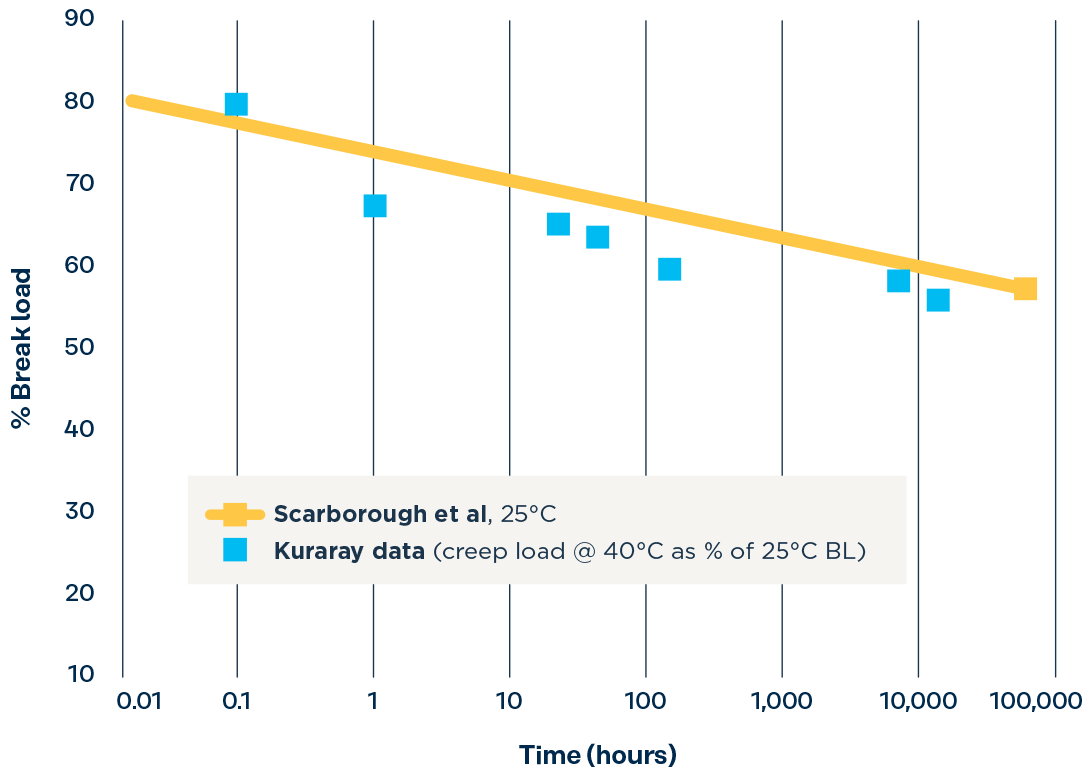

Creep rupture

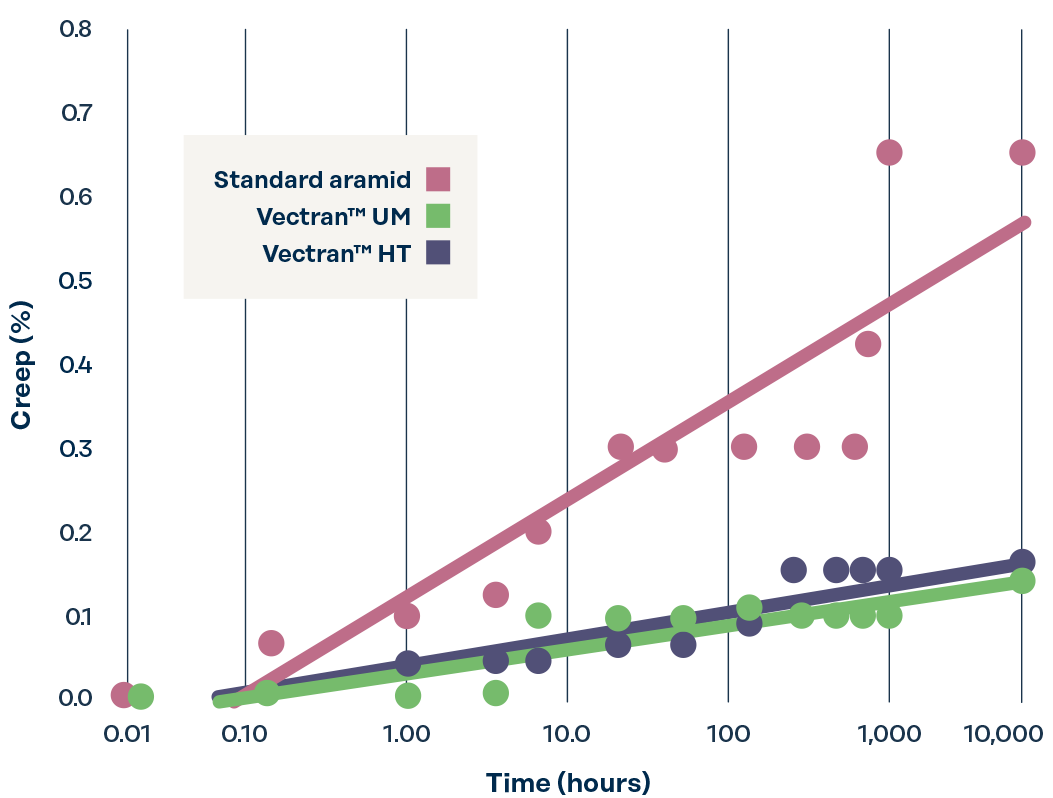

Creep behavior at ambient temperature (30% of break load)

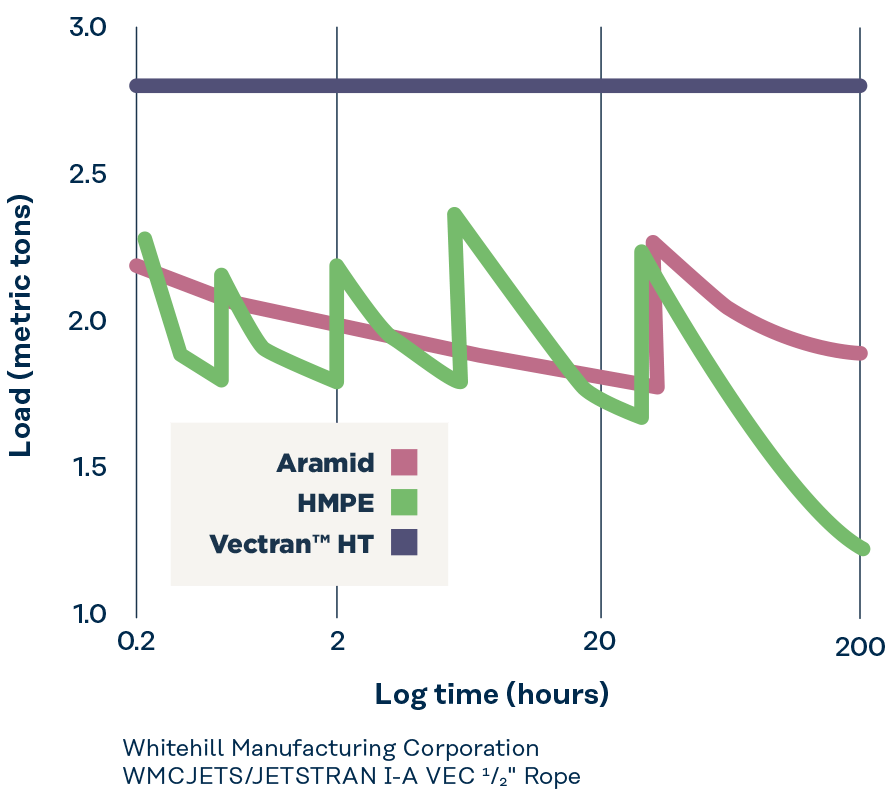

Stress relaxation (13 mm dia. wirelay rope)

External abrasion resistance

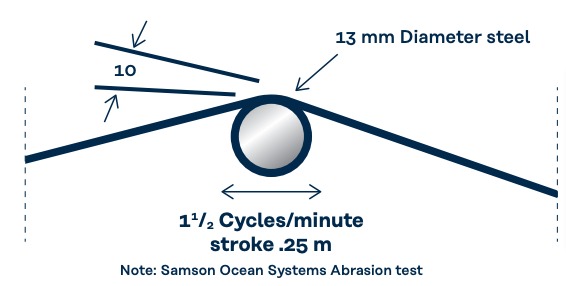

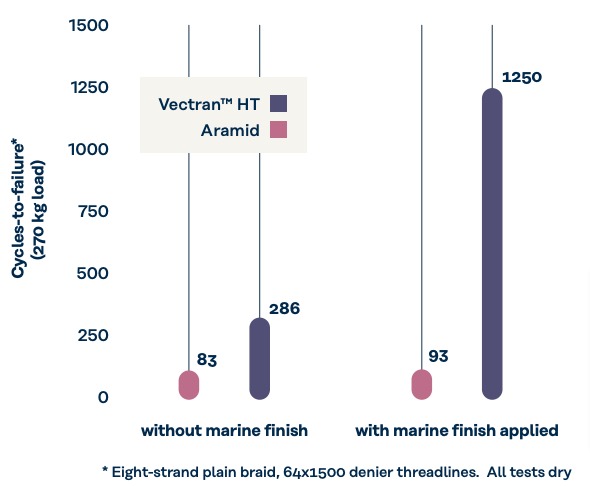

Abrasion test comparisons of Vectran™ and aramid braids were conducted by a high-performance rope and cable company using the test shown.

With or without a marine finish on the braid, Vectran™ outperforms aramid materials.

Yarn-on-yarn abrasion resistance

Fatigue resistance can be measured using the rope and cordage industry standard known as the yarn-on-yarn abrasion test (Cordage Institute test method CI-1503). This test simulates abrasion of adjacent yarns inside a rope or ropesplice during flexure. Using this test, the combination of wet and dry abrasion resistance by Vectran™ outperforms competitive materials like aramids and HMPEs.

Comparative testing of

yarn-on-yarn abrasion

resistance

| Average cycles-to-failure | ||

| Yarn | Dry | Wet |

| Vectran™ T97, 1500D | 16,672 | 21,924 |

| Aramid 1, 1500D | 1,178 | 705 |

| Aramid 2, 1500D | 1,773 | 759 |

| Aramid 3, 1500D | 974 | 486 |

| PBO, 1500D | 2,153 | – |

| HMPE, 1500D | 8,518 | 23,619 |

Test method CI-1503: 1.5 wraps, 500g load, 66 cycles/min, no twist.

Yarn-on-yarn abrasion of Vectran™ HT

| Cycles-to-failure* | ||||

| Dry test | Wet test | Dry test | Wet test | |

| Test Load | 500 g | 500 g | 800 g | 800 g |

| Vectran™ HT | 12,987 | 30,519 | 3,581 | 16,524 |

| Aramid | 939 | 3,029 | 422 | 1,719 |

1500 denier yarns, no twist, 1 wrap